Value Chain Solutions Inc.

Sustainable Solutions for Oil Sands Industry

& Global Refineries

Our Solutions.

VCS provides Full Value Chain (“FVC”) solutions to address the significant challenges facing the oil sands industry.

-

With the VCS-H bitumen will be transformed into high value refined products and premium medium crudes to help debottleneck pipelines and add value in Alberta along with reducing diluent import requirements and repurposing import pipelines,

-

Taking advantage of the industrial cluster in the Alberta Industrial Heartland and creating product interfaces between the petrochemical industry and VCS-H for greater efficiencies and value addition,

-

Establishing a new clean oil stream – VCS Premium Medium Crude Oil (COLF) which is more socially, environmentally and politically acceptable to help resolve stakeholder issues – allowing for diversification with export market development, and

-

Creating an Inventory Market Management (IMM) - a Strategic salt cavern storage in synergy with VCS-H Complex processing capacity. IMM will serve as a tool to help balance supply and demand as well as stabilization of the volatile light/heavy differential as an alternative to production cuts.

VCS will transform the Oil Sands Industry to Clean Oil Industry

COLF Crudes - Optimal Fit for Global Refineries

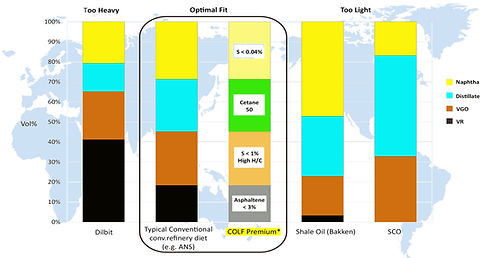

COLF characteristics optimally fit conventional refineries.

COLF Premium is produced by purposely blending multiple product streams to achieve a product with distillation yields almost identical to a conventional medium crude oil such as ANS.

Since many large conventional refineries were designed based on conventional medium crude oils, a new feedstock with nearly identical distillation yields means that all major process units can be fully utilized.

The unique characteristics of COLF Premium not only fit the majority of the world’s conventional refinery, but hold significant potential for additional refining margin uplift as the quality of low MCR and nearly no asphaltenes in Vacuum Residue is especially valuable. The vacuum residue is much easier to crack with higher product yields and lower coke production in delayed coking, has much higher conversion in residue hydroprocessing and visbreaking, and has much lower catalyst poisons in catalytic processes.

The lower sulphur, higher cetane, and higher H/C ratio will all help refineries in meeting upcoming higher specifications for their products, while boosting their profit margin.

COLF Crudes - Diversifying Markets

The market gap for optimal medium crudes is widening, with fast growth of light shale oil and heavy bitumen.

By far, the majority segments of North America (and Global) refineries are conventional conversion refineries (with catalytic crackers and/or hydrocrackers , and limited residue processing).

VCS Releases Pipeline Capacity

For every barrel of DilBit processed through VCS-H, there would be more than 70% volume capacity freed up for additional oil transport.

VCS-H is able to optimize utilization of current pipeline capacity through the upfront removal of asphaltenes, utilization of rail transportation for the high value/quality specialty refined products, provision of LPG streams to local petrochemical facilities, and diluent return to regional Edmonton market.

VCS-H, when fully completed, possesses the capability to debottleneck major long distance pipelines significantly, enabling bitumen production growth within current pipeline infrastructure.

VCS Reduces Green House Gas Emissions

VCS’s unique upgrading will reduce the total life cycle emission as the De-Carbonization (and De-Contamination) of bitumen upfront is a unique “Upgrading” process. ADC™ produces clean oil that enables high conversion thermal cracking and hydroprocessing to produce COLF premium medium crude oil to feed conventional refineries plus the specialty refined products.

VCI’s technologies will bring about 13-16% GHG emission reduction on the basis of Wells-to-Tank Life Cycle Analysis (“LCA”) or 25% for DilBit-to-Tank LCA. Overall, the changes of higher fuel gas, lower electricity requirement, higher product volume, rail transportation of refined products due to optimization did not change the overall GHG emission reduction life cycle results significantly. As shown in the Figure, the LCA GHG emission reduction (25% from DilBit to Tank) stays the same on bitumen basis, while there is an increase in product yield for the whole cycle due to our optimization.

Inventory Market Management ("IMM")

VCS will use its salt cavern storage as alternative to production curtailment.

IMM will serve as national crude strategic reserve.